How a Television Is Born: Behind the Scenes in the Factory

In the wave of modern technology, television remains the core of home entertainment. Its assembly process reflects advanced automation, precise craftsmanship, and strict quality control. Today, let’s take a closer look at how a TV is assembled step by step in the factory.

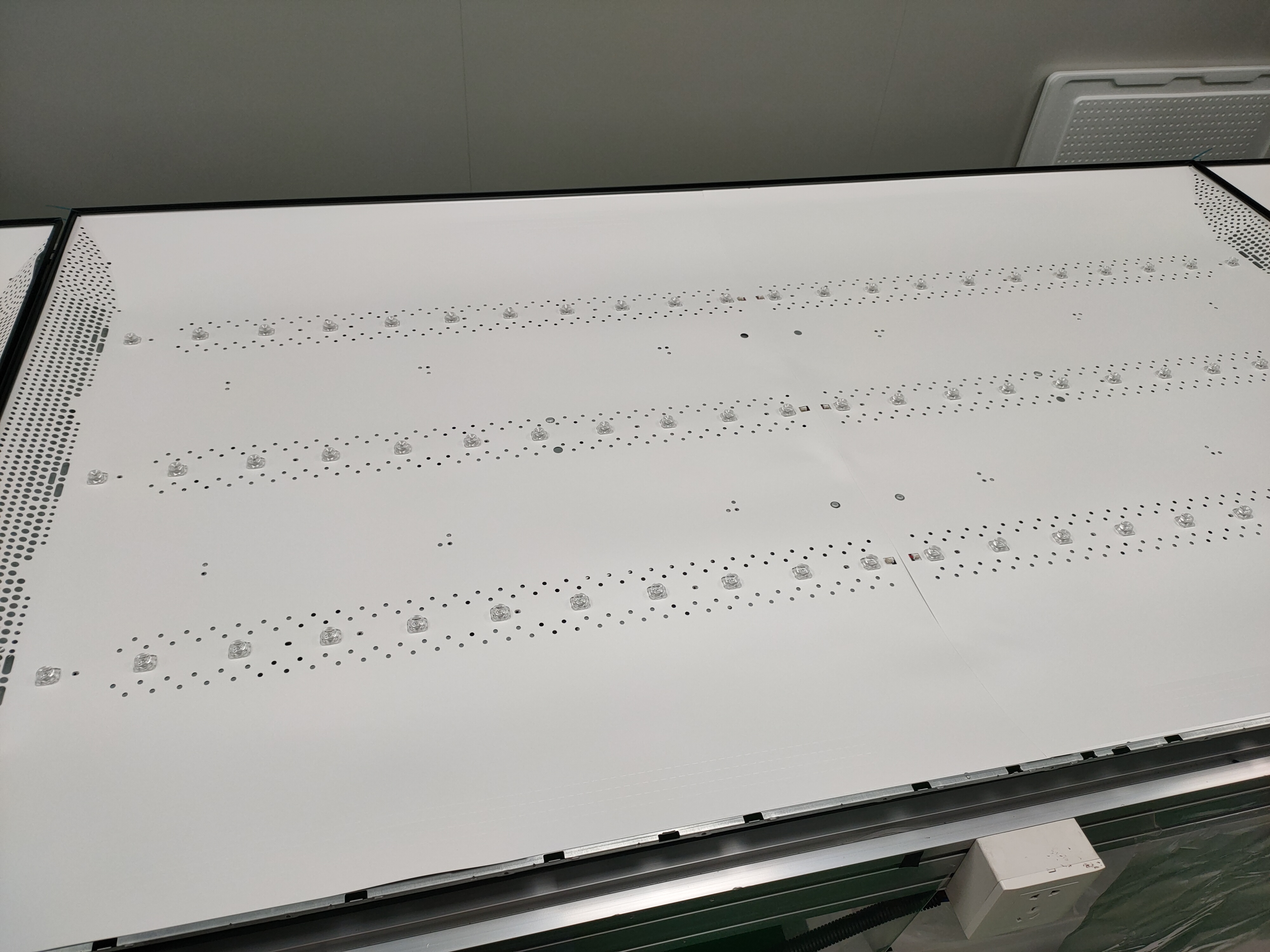

1. Backlight Assembly and Clean Room

The backlight system is essential for clear and bright images. It usually consists of multiple LED strips mounted on the TV’s back panel, ensuring even lighting across the screen. Assembly takes place in a dust-free clean room, where strict air quality controls prevent dust from affecting the TV’s performance and lifespan. Here, workers also install the glass panel, which must fit perfectly with the backlight for optimal image quality and color.

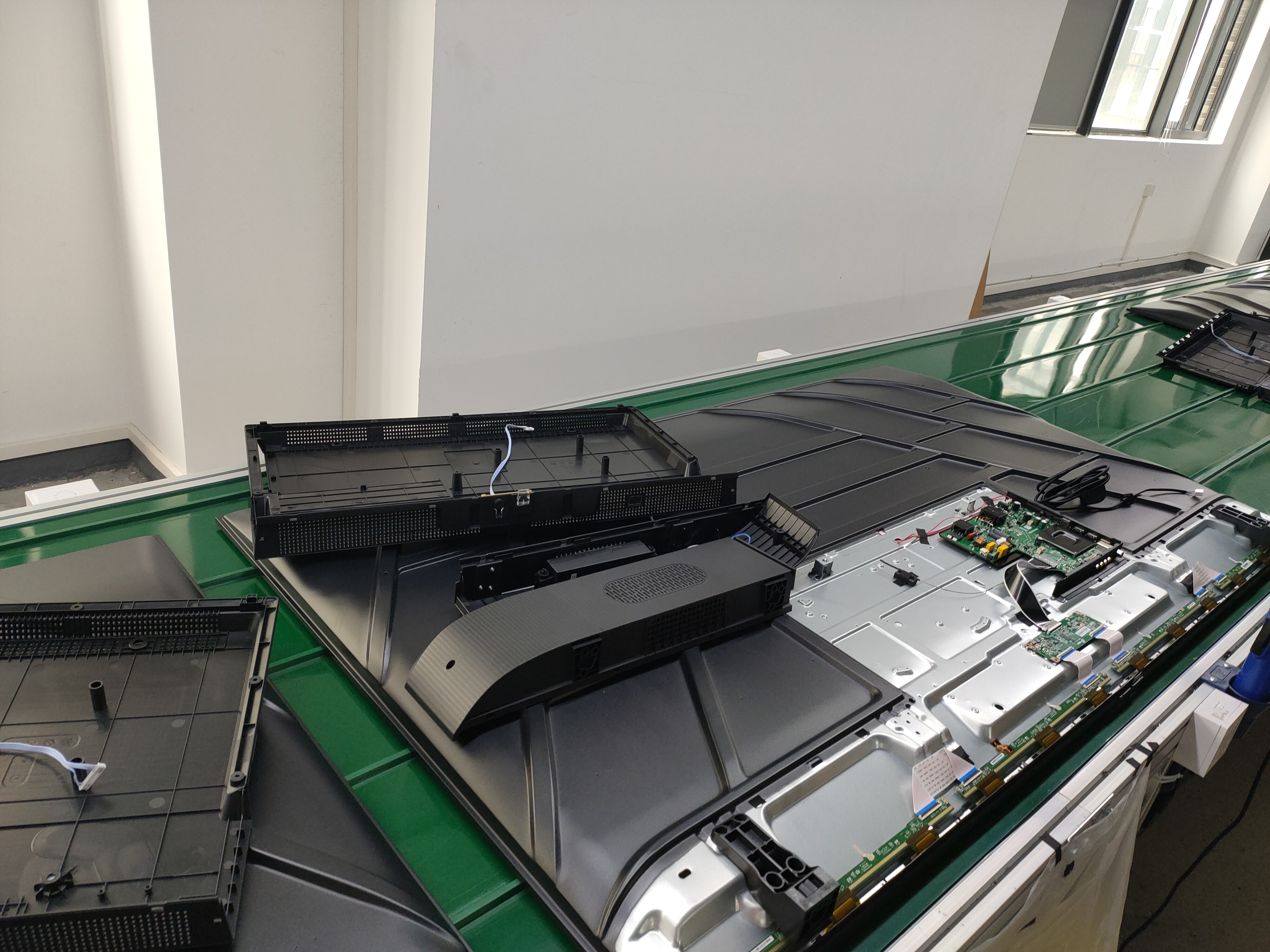

2. Main Component Assembly

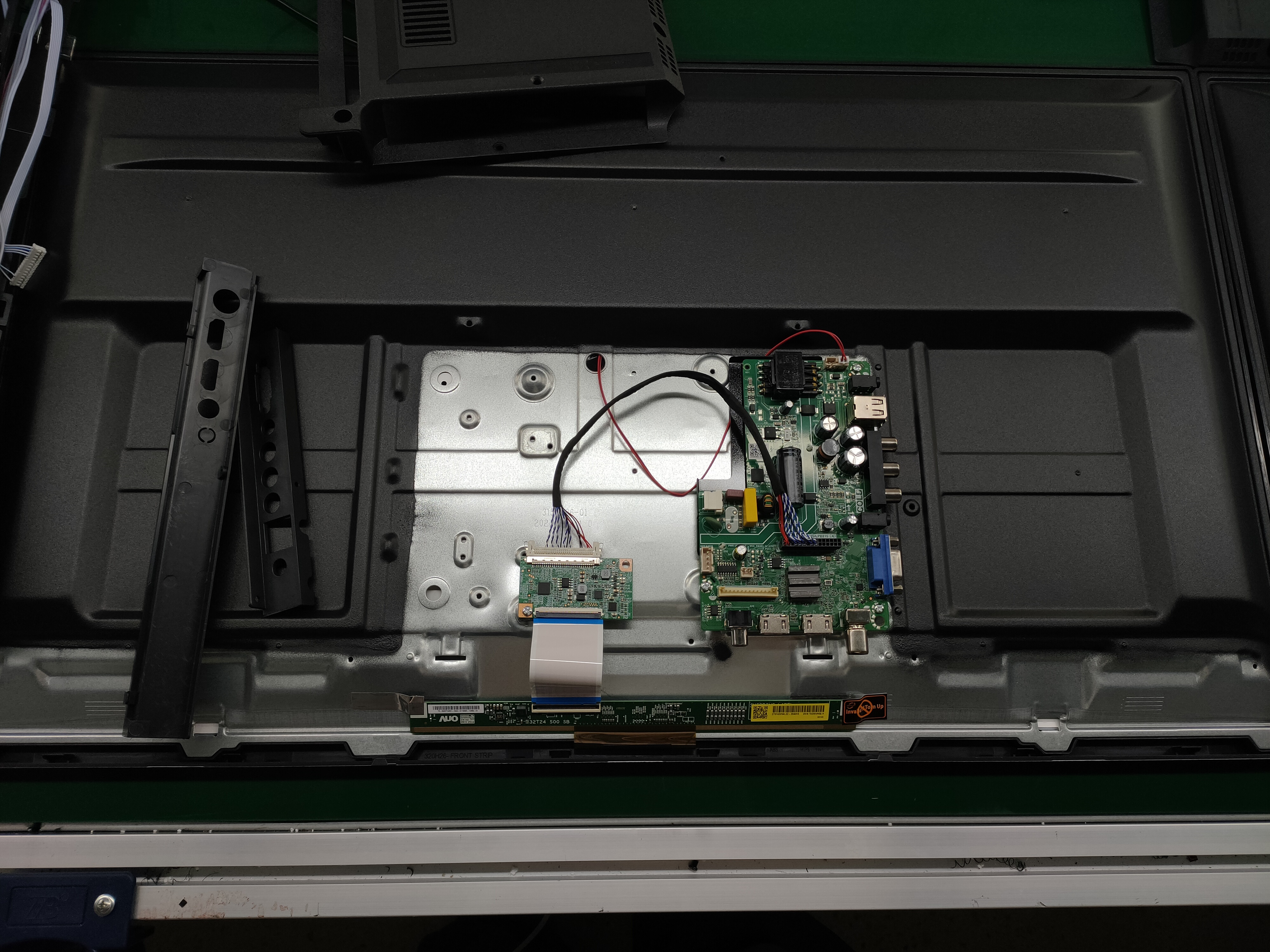

After the glass panel is installed, the TV moves to the main assembly line. Here, key parts are installed, including the mainboard, speakers, and power module.

- Mainboard: The “brain” of the TV, controlling all functions like signal processing and audio output. Workers fix the mainboard inside the frame and connect all necessary cables.

- Speakers: The “voice” of the TV, installed on the sides or bottom for balanced sound.

- Power Module: The “heart” of the TV, providing stable power supply.

Other parts, such as remote control receivers, antenna ports, and USB ports, are also added to ensure full functionality.

3. Aging Test

Once assembly is complete, each TV goes through an aging test. This means running the TV continuously for over 24 hours to check for any issues like black screens or lines, and to ensure heat resistance and reliability.

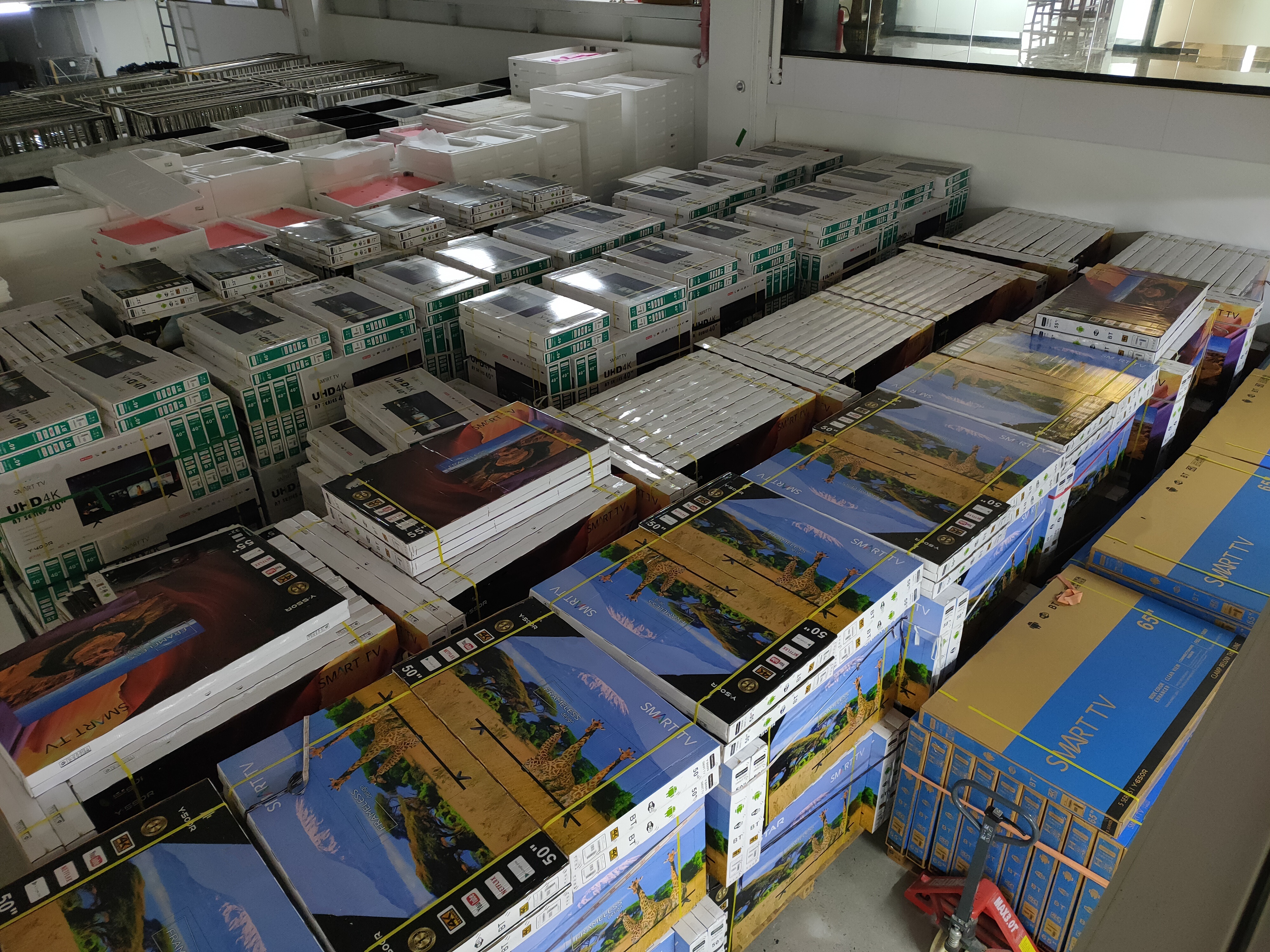

4. QC Inspection and Automated Packaging

After testing, TVs go through strict quality control checks. Workers inspect each unit for missing or loose parts, and test the image, sound, and remote control functions. Only TVs that pass all tests are packaged. Automated packing machines improve efficiency and make sure each TV is securely packed for protection.

Packaged TVs are stored in the finished goods area, sorted by model and batch, ready for shipment.

5. Conclusion

From backlight assembly to final packaging, every step in the TV assembly process is carefully managed. This dedication to quality ensures our customers remain competitive in their local markets.